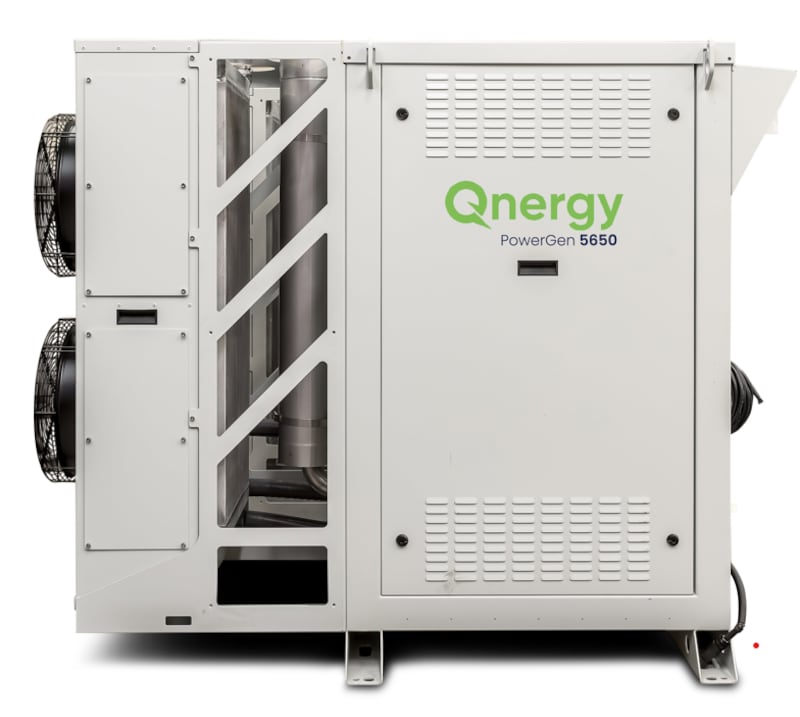

Photo courtesy of Qnergy

While carbon dioxide has long been the focus of global greenhouse gas emissions campaigns, another key front in the critical fight against climate change is reducing methane emissions. Utah-based Qnergy could be at the center of that battle with its new abatement systems.

According to the International Energy Agency, methane is responsible for about 30 percent of the rise in global temperatures since the industrial revolution. Some methane is produced naturally, but it’s also released in the production of oil and gas, landfills and agriculture, where it’s released from animals’ digestive processes.

Those human-impacted actions are where Qnergy comes in. The company develops methane abatement systems for methane-producing processes across the globe that can help turn methane that would have been wasted back into electricity.

As part of natural gas production, pneumatic devices “release or bleed natural gas to the atmosphere,” the EPA states. Qnergy’s systems are designed to “capture” that methane as it is released, Qnergy VP of Business Development Kevin Pang says.

“Now you’ve got yourself a really simple, elegant solution because you don’t have to change the infrastructure,” Pang says. “You just drop in, connect it to the well pad, and you’re up and running.”

Photo courtesy of Qnergy

In 2021 alone, Qnergy claims that its methane abatement systems mitigated over 150,000 tons of methane emissions, and they’re in growth mode. Qnergy CEO Ory Zik says that over 1,500 units are already in use, and the company is aiming for another 10,000 in the “next few years.” He says that is equivalent to removing 3 million cars from the road.

“Given the pressing need to address greenhouse gas emissions and global warming, significant solutions are required. Qnergy aims to be a major contributor to climate change mitigation, with methane being a crucial target as the second most important greenhouse gas after CO2,” Zik says, adding that the company has achieved an annual growth rate of 70 to 100 percent annually over the past five years. “We intend to continue this trajectory, and even accelerate it, to meet the ever-growing demand for our products. Qnergy is committed to scaling up to address this challenge head-on.”

Qnergy was founded by investors who bought a Stirling engine company called Infinia, originally based in Washington state with a facility in Ogden.

Stirling engines have pistons that are powered and moved by repeatedly heating and cooling air. Zik says Qnergy is the only Stirling generator manufacturer, which the company considers highly important for remote power generation.“Qnergy has successfully accomplished what many deemed impossible: developing a commercial power generator based on the Stirling engine,” Zik says. “Engineering professors often teach why such a feat is extremely challenging, if not impossible. However, we have already deployed over a thousand of these ‘impossible-to-build’ generators. Making the ‘impossible’ a reality is an incredibly gratifying achievement.”

The company initially focused on Stirling engines for defense, space and solar energy. Zik joined the company in 2017 as an advisor to the board before moving into the CEO chair. After that, the company shifted entirely to climate change solutions, specifically methane abatement. So far, it’s been a success.

“Qnergy exemplifies a company that can achieve financial success while simultaneously doing good for the environment. Our climate benefits are substantial,” Zik says. “For example, our last year deployments managed to reduce greenhouse gas emissions by an amount equivalent to the emissions produced by all the cars in Ogden. As we continue on our current growth trajectory, we anticipate achieving the same emissions reduction as all the cars in Utah by 2025.”

The future challenge of methane abatement is removing it from rising air; this is common with free-ranging cattle and natural wetlands processes. When concentrated, like in oil and gas operations or indoor cattle operations where the methane can be channeled, methane abatement is a little simpler.

But there’s no time like the present to start. There’s a lot of work to be done.

“It’ll take decades and lots of R&D to be able to make that work,” Pang says. “But it’s the 80-20 rule, right? So if we can, it’s the first 20 percent on the largest farms, then the next 80 percent. Let’s go after those, and then you can kind of break those into subsegments.”